{{sole.name}}

Meet the Factory

Over 35 years of experience offering our partners a wide range of solutions, from EVA to thermoplastics.

We have the largest rubber injection factory in Europe in a 24/7 continuous production line all in the same open space site.

Certifications

Visit our website

bolflex.ptEverything in one place.

Bolflex is the only components manufacturer that builds its own moulds inhouse.

We vertically control every single step of the developing process with our own CAD designing office, our 3D machinery, CNC and casting facilities.

We produce mockups, moulds and then inject the final product.

We are unique and autonomous, flexible and agile.

Here, you can find:

Design, Prototyping, Molding, Laboratory, Production but also an unique recycling facility - Rubberlink

RubberlinkKnow more on our website

One Stop ShopSustainability 2.0

Green is the new Gold.

Rubber Waste Recovery

Through our innovative method called devulcanization, we produce “virgin” rubber made out of industrial rubber waste, mainly from our production line.

Once we transform this previous waste into new raw-material we can reuse it again to build new products.

It’s a 0% waste solution and a full circular process.

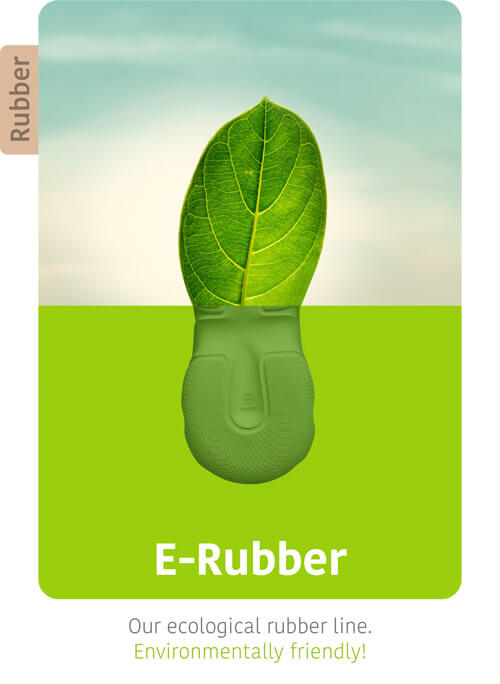

The new generated raw-material is named e-rubber, which we can incorporate over 50% in a new outsole depending on the desired outcome.

Know more on our website

Sustainbility 2.0Old shoes make new soles

"360 S" is a new material that we have developed by applying the devulcanization process to entire old grounded shoes.

We can give new life to old shoes in the shape of a new outsole.

Old shoes are walking again!

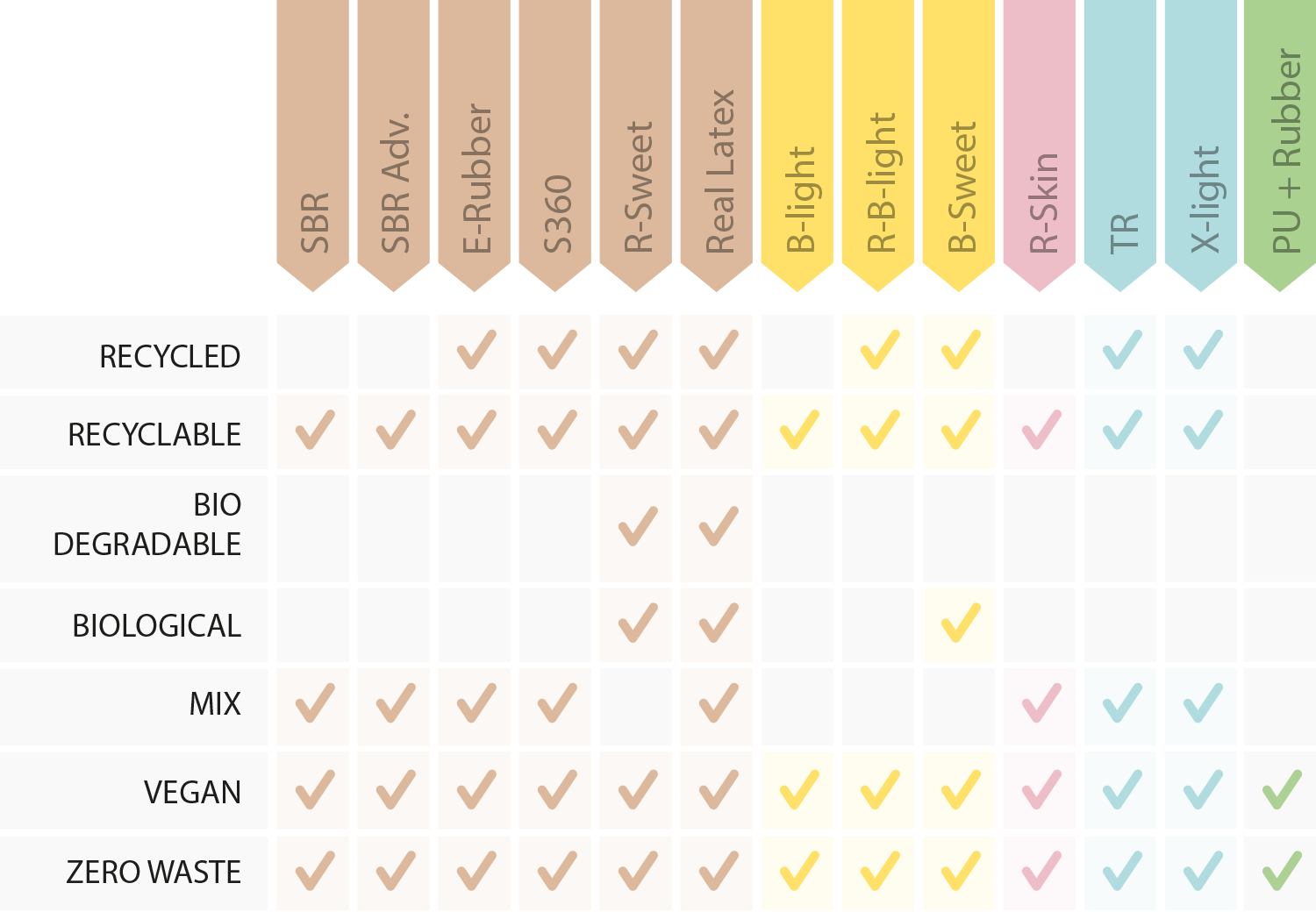

Materials

Contact us

Phone

Tel. +351 255 495 459

Tel. +351 255 495 461

(call to local landline)

Address

Rua Nicolau Coelho

N.º 3315 Felgueiras

4610-741 Sendim

Portugal

Try It

Take photo

Download

Download

Choose background:

Back

Get a Sample

{{ sharedListTitle }}

{{ myListTitle }}

{{sole.name}}

Share list

Edit list

{{ selectedSole.name }}

Color {{index}}: {{ part.color_default }}

Material: • {{ colorMaterials[material].description }}

Collection: {{ selectedSole.sizes.scale }} {{ size }}

Type: {{ selectedSole.use_type }}

Downloads

Share

Delete

Add to list

Try it

Search